Welcome to Vipra Pharmaceuticals

Manufacturers of Allopathic Medicines, Healthcare Products

Established in 2011, Vipra Pharmaceuticals is a pharmaceutical company specialized in the development, production and marketing of generic drugs for domestic & for Export. Vipra Pharmaceuticals in Pune has GMP approved production unit, marketing, sales and distribution centre in Pune, Mumbai, Punjab, banglore.

With a production capacity of 79 cr capsules per year, Vipra Pharmaceuticals has objective to expand and grow its strategic position as a leader in generic market of India.

Since 2013 Vipra Pharmaceuticals made their international presence in 25 countries in Africa and Middle East. Over 62% of total sale is now contributed by international operations.

The plant is located at Gat.No.439, Village – Bebadohal, Tal. Maval, Pune 410506, Maharashtra, India. This is in closer vicinity to the Mumbai –Pune National High Way (NH 4) & 40 km. from Pune city. There is no polluting factor in the vicinity of the unit thereby offering a neat and suitable condition for manufacturing of pharmaceuticals. The total plot area is 33000 sq. meters. The built up area of the plant is of 5500 Sq. meters. The factory building has a ground floor.

Our facilities are well equipped with latest manufacturing, automatic, semi-automatic, high speed, GMP machines and equipments to yield quality products with highest quantity output with modern packaging facility like blister packaging, strip packaging, shrink wrapping, laser ink batch coding, high speed automatic sticker labeling application etc. Utilities like D.M. Water System, Air Handling Units, Air Compressor,Chillers, Dust Collector and Electrical Transformer are housed in outside area under secured shed.

QUALITY

QA is totally organized and arrangement with object of ensuring that the medicinal products produced are of the quality required for intended use. The QA system appropriates for the manufactured of medicinal products designed & developed as per GMP & GLP.

Production and control operations are clearly specified all necessary controls such as in-process, validations are carried out; finished products are correctly processed and checked.

GMP is a part of quality ensures that products are consistently produced & controlled to appropriate quality standards.

QC is a part of quality assurance concerned with specifically testing with proper documentations and list procedures in which respective tests are actually carried out.

The facility has adequate number of personnel with necessary qualification & practical experience. Organogram is available and all key personnel's job description and respective authority are displayed. The production head ensures products are manufactured & stored with proper documentation, maintenance of his department & premises. Appropriate validations are completed. Quality head is having authority to approve/ reject material / in process/ finished product by evaluation of proper documentation.

Personal hygiene, detailed hygiene programme are established which includes health, hygiene practices & clothing of personnel. All persons are going through a medical examination and are periodically checked in which infection disease, open lesions are properly advised.

The premises are designed in such a way that man movement / material movement is segregated to avoid contamination. All manufacturing areas are provided with class 100000 with positive pressure to avoid risk of cross contamination. Lighting provided is of 300 Lux. Temperature not more than 25 ̊C.

All equipments used are logically positioned and are easy for cleaning. Cleaning procedures are established for every equipment, in cases where dust is generated are provided with RLAF.

Storage area is sufficient to allow orderly storage of various materials. We have controlled Temperature storage areas also.

QC area is separate from production area and designed to suit to carry out the operations. Separate areas are provided for chemical, instrumental & Microbiological tests. We have separate microbiological laboratory which is class 100000 and having separate area for media preparation / bioassay / MLT.

Ancillaries such as change rooms, washing & toilets are properly arrange to facilitate the movement of people.

IMPLEMENTATION OF QUALITY POLICY:

- To achieve quality objective a strong Quality Assurance system has been Formulated, incorporation Good Manufacturing Practices & Good Laboratory Practices.

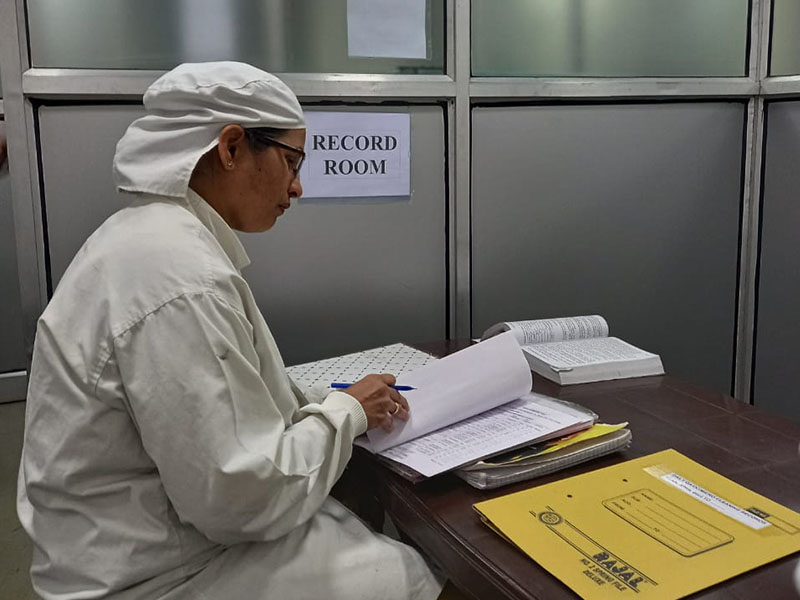

DOCUMENTATION:

- QA ensures that the manufacturing process have approved & authorized Standard Operating Procedures and all products have authorized Master formula Records.

- Relevant SOPs that cover all manufacturing operations are available.

- All in process checks & controls at various stages in the process of Manufacture are recorded

CALIBRATION & VALIDATION:

- All manufacturing equipment & process are validated as per the Validation protocol

- All testing, indicating & recording instruments are calibrated as per Protocol.

TRAINING:

- The training of employees is conducted on a regular and ongoing basis

- Regular maintenance is given due importance & is carried out as per planned schedule.

OUR PORTFOLIO

Today, more than 50 products are marketed and used to treat patients in 25 countries worldwide.

Our products cover a wide range of therapeutic categories offering oral solid dosage forms.

With our expertise in the production from Active Pharmaceutical Ingredient (API) till finished product, Vipra Pharma can guarantee to all their customers and partners, large volume of world class medicine at affordable price and dedicated and cooperative customer’s services.

Vipra Pharma has also a strong pipeline of products under development and a large number of products pending regulatory approval. Our Regulatory team have key skills to develop and register the drugs as per regulatory requirements.

With a current manufacturing capacity reaching 79 Cr capsules per year, our customers can be ensured of reliable delivery of our products and our ability to meet high demand. Our uniformed network of manufacturing facilities and vertically integrated distribution guarantees satisfaction for all your needs.

INFRASTRUCTURE

Our Production Capacity :

- At present we are catering to more than 17 allopathic pharma companies with their own brands.

The installed capacities for various sections are as follows :

- Capsules – 21 lacs per day.

Capsules

Vipra Pharma manufactures over 30 Allopathic products as per the various pharmacopoeia references. We developed branded proprietary products, which are either curative or health supportive in their health care functions. We have expertise in manufacturing of allopathic products having common and specific indications as follows :

| # | Product Name |

|---|---|

| 1 | Antacid Capsules |

| 2 | Antiallergic, Capsules |

| 3 | Anti-inflammatory Capsules |

| 4 | Multivitamin Capsules |

| 5 | Pain Reliver Capsules |

| 6 | Anti-emetic Capsules |

| 7 | Anti-Diarrheal Capsules |

| 8 | Anticonvulsant Capsules |

| 9 | Antibiotic Capsules |

| 10 | Haematinic Capsules |

| 11 | Analgesic, Antipyretic Capsules |

| 12 | Anti-Rheumatic Capsules |

| 13 | Anti-cold capsules |

| 14 | Anti-fungal Capsules |

| 15 | Capsules to treat sore throat |

Team

Managing Director's Message

Vilas Bhargude

MANAGING DIRECTORFormulation facility at Vipra pharmaceutical

Vipra Pharma is G.M.P. certified & Allopathic Products manufacturing company. We manufacture allopathic and health care products on third party and loan license basis, Under supervision of well qualified and trained staff we manufacture more than 50 Allopathic Products in the form of Capsules. We deal in wide array of Allopathic Products.

Our target within next few years is to use maximum advantage of medicines in capsule dosage form and promote it on the global level. To do so we are using our brand equity, vast experience, research capabilities, core knowledge and capability.

From the past few years we have successfully created a high standard position in domestic as well as in international market. The products offered by us are pure, qualify and quantify and hygienic. These products are of better quality and free from any side effect. Our commitment to social health care through quality products with proven efficacy leads to satisfaction of society.

Contact Us

Address

Gat No.439, Village Bebadohal, Tal: Maval, Dist : Pune Pune 410506, Maharashtra, India.Phone Number

GST No.

27AAFFV8412Q1ZHUDYM Reg.

MH-26-0108846

VAT TIN No.

27490921712V